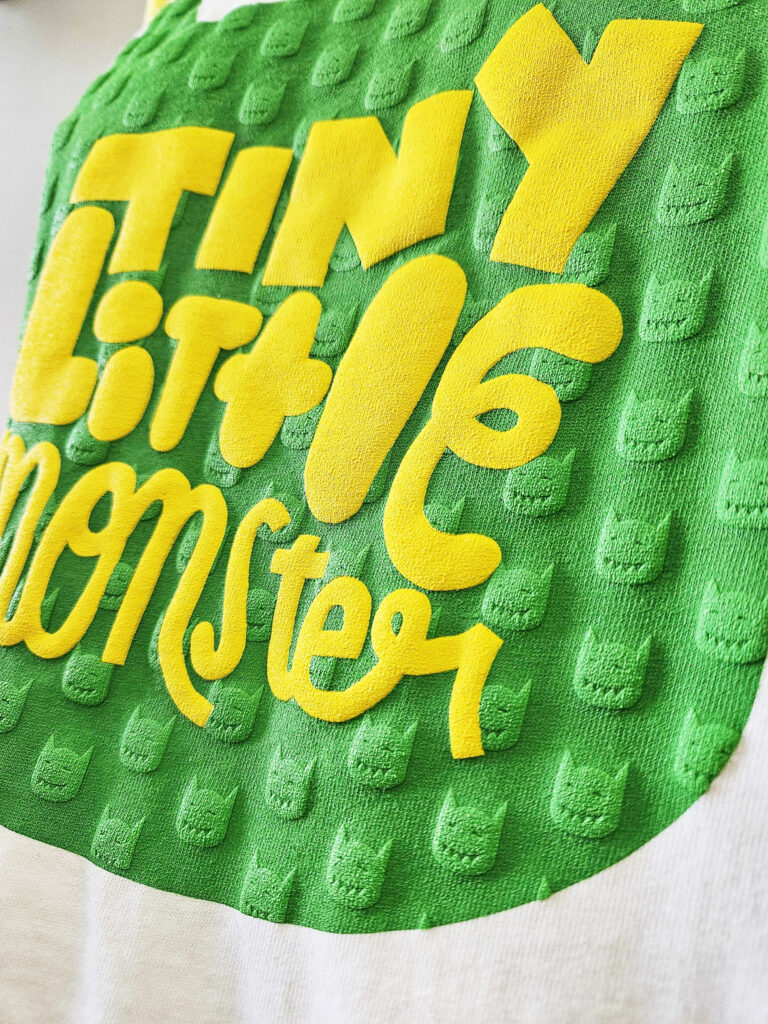

When it comes to screen printing, the possibilities are as expansive as the ink itself—especially when using puff screen printing! This printing method offers a tactile and unique visual appeal that traditional inks can’t achieve. Here at Tiny Little Monster, we’re excited to share the ins and outs of printing with puff ink, from its unique characteristics to practical design tips and care instructions.

What is Puff Ink?

Puff ink is a plastisol-based ink enhanced with a heat-reactive foaming agent. When the ink is exposed to heat during the curing process, it expands, creating a three-dimensional, raised effect on the fabric. Think of it as the “bread dough” of the screen-printing world—it rises beautifully under the right conditions.

Why Choose Puff Screen Printing?

Benefits of Puff Ink

- Depth and Texture: Puff ink adds a raised, tactile element to your design, making it pop—literally.

- Versatility: Puff ink works with multiple colors and can enhance specific elements of your artwork for added emphasis.

- Fabric Friendly: It can be applied to most types of fabrics without compromising the garment’s integrity.

Challenges to Consider

- Design Limitations: Puff ink works best with bold, thick lines; fine details (smaller than 1–2 mm) can be lost in the expansion.

- Pantone Color Matching: The foaming agent can slightly alter the color, especially darker hues.

- Fabric Thickness: On thinner garments, the underside of the print may feel slightly puckered.

Design Tips for Puff Ink Printing

Keep It Bold

Puff ink shines with simple, bold designs. Choose fonts and linework with thicker widths to maximize the raised effect.

Highlight Specific Details

You can use puff ink to accentuate specific parts of your artwork rather than applying it across the entire design. This technique draws attention to key elements and adds dimension selectively.

How Puff Ink is Made and Applied

Puff ink is created by adding a puff additive to standard plastisol inks at a 5–15% ratio by weight. The amount of additive determines how much the ink will rise during curing. The ink is then printed onto the garment and cured in a dryer, where heat activates the puff effect—similar to baking bread.

Caring for Puff Prints

To keep your puff-printed garments looking their best:

- Wash Inside Out: Use cold water to preserve the integrity of the design.

- Avoid High Heat: Skip the tumble dryer; air dry your garment to prevent any damage.

- No Ironing Over Prints: Heat can flatten the puff effect, so iron around the print area if needed.

When to Use Puff Ink

Puff ink is perfect for:

- Bold Logos: Make your brand stand out with a three-dimensional logo.

- Event Merchandise: Add texture to limited-edition designs for a unique, high-end feel.

- Statement Pieces: Bring life to specific design elements with a raised effect.

At Tiny Little Monster, we love helping our customers bring their creative visions to life. Puff ink is one way to add dimension and character to custom apparel. Whether you’re looking for bold statement pieces or subtle accents, puff ink is a fantastic way to add a new dimension to your designs—both literally and figuratively.

Ready to explore the possibilities? Contact us to learn more about our puff ink options and how we can help your next project stand out from the crowd!